Forbes Marshall Valves & Steam Traps Dealers, Distributors & Exporters in Mumbai & Pune

Forbes Marshall Valves & Steam Traps

We are a leading dealer, supplier, trader, and stockist of Forbes Marshall valves and steam traps based in Mumbai. With a commitment to delivering high-quality and reliable products, we provide effective solutions for industries that require efficient fluid and steam management. Our Forbes Marshall products are engineered to optimize operational performance, energy efficiency, and system reliability across various applications.

Our Offerings:

Valves: A Comprehensive Range Of Valves Suitable For Different Processes, Ensuring Efficient Fluid Control And Management. Steam Traps: Reliable Steam Traps Designed To Remove Condensate While Conserving Energy And Improving System Efficiency.

Why Choose Forbes Marshall Products?:

- Proven Quality and Durability: Forbes Marshall is renowned for manufacturing high-quality industrial products designed to last and perform consistently.

- Innovative Technology: With continuous advancements in engineering, Forbes Marshall products are equipped with the latest technology to optimize system efficiency.

- Comprehensive Solutions: Whether you need valves, steam traps, or both, we provide a full range of products to suit your industrial applications.

- Prompt Delivery & Excellent Service: As a leading Forbes Marshall stockist in Mumbai and Pune, we ensure fast delivery and reliable customer service to meet your needs.

Get in Touch with Us Today!

Looking for reliable Forbes Marshall valve and steam trap dealers? We are here to provide you with high-performance industrial solutions at competitive prices.

Contact us today to learn more about our products or to place an order.

Forbes Marshall Piston Valve

Description

Forbes Marshall Piston Valves, Psval, Provide Perfect Tightness And Durable Stability On Different Media Such As Steam, Superheated Steam, Heat Transfer Fluid, Water And Compressed Air.

Sizes And Pipe Connection

1. Dn 15 / 20 / 25 / 32 / 40 Screwed Bspt / Npt / Bsp, Socket Weld Ends, Flanged To Class 150 / 300 / 600 Available On Special Request Body Design As Per Class 800 - Available On Request

2. Dn 50/65/80/100/125/150/200/250/ Flanged To Class 150/300

3. Dn50/65/80/100/125/150/200/250 Flanged To Pn16/Pn25/Pn40

For Higher Sizes Dn250 And 300 Contact Us

Limitingconditions

For Dn 15 / 20 / 25 / 32 / 40 Socket Weld Ends

-Maximum Operating Pressure: 78 Bar G

-Maximum Operating Temperature: 425 Deg C

-Maximum Hydraulic Test Presure: 156 Bar G (Ibr Requirement)

For Dn 15 / 20 / 25 Screwed Ends

-Maximum Operating Pressure: 78 Bar G

-Maximum Operating Temperature: 425 Deg C

-Maximum Hydraulic Test Presure: 156 Bar G (Ibr Requirement)

Or Dn 32 / 40 Screwed Ends

-Maximum Operating Pressure: 41.5 Bar G

-Maximum Operating Temperature: 425 Deg C

-Maximum Hydraulic Test Presure: 83 Bar G (Ibr Requirement)

Body Design Conditions:

Dn 50/65/80/100/150/200/250 Class 150 Flanged End

-Maximum Operating Pressure: 19.6 Bar G

-Maximum Operating Temperature: 425 Deg C

-Maximum Hydraulic Test Presure: 28 Bar G (Ibr Requirement)

Body Design Conditions:

Dn 50/65/80/100/150/200/250 Class 300 Flanged End

-Maximum Operating Pressure: 51 Bar G

-Maximum Operating Temperature: 425 Deg C

-Maximum Hydraulic Test Presure: 83 Bar G (Ibr Requirement)

Forbes Marshall Y Strainer

Description

Forbes Marshall Cast Strainers, Fmstr34, Fmstr54 / Fmstr54#600 Are Available In Cast Iron / Cast Steel With Ss Screen Having 0.8mm Dia Perforation As Standard Up To Dn 125.

Sizes And End Connections

-Ci : Dn40, 50, 65 ,80, 100,125, 150 And 200

-Cs : Dn40, 50, 65 ,80, 100,125, 150, 200, 250 And 300

Note:

1. Also Available With Ibr Certificate On Request

Limiting Conditions

For Ci Strainer-Fmstr34

-Pmo Maximum Operating Pressure For Saturated Steam Service 13 Bar G

-Tmo Maximum Operating Temperature 220 Degree

-Designed For A Maximum Cold Hydraulic Test Pressure Of 26 Bar G

Limiting Conditions

For Cs Strainer-Fmstr54

-Pmo Maximum Operating Pressure For Saturated Steam Service 58 Kg

-Tmo Maximum Operating Temperature 425 Degree

Forbes Marshall Moisture Separator

Description

The Forbes Marshall Moisture Separator, Fmsep54, Is A Carbon Steel Baffle Type Separator Used For The Removal Of Entrained Liquids In Stream, So That They Cab Be Drained Away As Condensate.

Sizes And Connections

-Sizes: Dn25, 40, 50, 65, 80, 100, 125, 150 And 200

Flange Connections

-Bs10 Table F, H, J, K, Asme B 16.5

-Class 150, 300, Pn10, 16, 25 And 40

Notes:

-Available With Ibr Test Certificates, On Request.

-Optional Insulation Packs Are Available Which Will Increase The Performance Of Separator.

Limiting Conditions

-Body Design Condition 32 Bar G At 425 Degree

-Cold Hydraulic Test Pressure 64 Bar G

Forbes Marshall Ci Prv

Description

The Forbes Marshall Pilot Operated Pressure Reducing Valves, Fmprv41 Is A Sg Iron Pilot Operated Pressure Reducing Valve Suitable For Steam Or Compressed Air.

Sizes And End Connections

-Dn15, 20, 25, 40, And 50

-Screwed: Bspt / Npt For Dn 15, 20, 25

-Flanged: Bs 10 Table “F/H” For Dn40 And 50

-Dn15 Fmprv41 Lc Version Available

Limiting Conditions

-Pmo-Maximum Allowable Pressure 17 Bar G

-Tmo-Maximum Allowable Temperature 232 Degree

-Cold Hydraulic Test Pressure 34 Bar G

-Spring Range 0.3 To 17 Bar G

Pressure Sensing Pipe

The Fmprv41 Controls The Pressure By Sensing The Downstream Pressure Through A Pressure Sending Pipe Taken To The Union (Item L) Or Through The Internal Sensing Pipe (Item M). Fitting Of The External Pressure Sensing Pipe Is Described In The User Manual Supplied With The Valve.

Note: Capacity Is Reduced And There Is A Possibility Of Hunting If An External Pressure Sensing Pipe Is Not Fitted.

Forbes Marshall Disc Check Valve

Description

The Forbes Marshall Disc Check Valves Compatible To Ansi Flanges, Fmdcvansi, Are Of The Wafer Pattern Designed To Be Sandwiched Between Flanges. They Are Suitable For Use On A Wide Range Of Fluids For Applications In Process Lines, Hot Water Systems, Steam And Condensate System Etc. Face-To Face Dimensions Conform To En558 Part 1 Series 52

Sizes And Pipe Connections

15, 20, 25, 32, 40, 50, 65, 80, 100nb Suitable For Installation Between Ansi Class 150 And 300

Optional Extras

-Viton Soft Seats For Oil, Gas And Steam Application. Epdm Soft Seats For Water Applications.

-Certification Available With Ibr With Metal Seating Only. All Certification / Inspection Requirement Must Be Stated At The Time Of Order Placement.

-Standard Designed And Manufactured In Accordance With Bs 7438.

Forbes Marshall Safety Valve

Description

The Forbes Marshall Safety Relief Valve Fmsrv Is A High Lift Safety Valve With Gun Metal Seat, Valve And Brass Internals Suitable For Use On Steam, Air And Water.

Size And Pipe Connections

-Dn 15, 20, 40, 50

-Screwed Bspt

-Available With Ibr Certificate

Limiting Conditions

-Pmo Maximum Operating Pressure 17.5 Bar G

-Tmo Maximum Operating Temperature 224 Degree C

-Cold Hydraulic Test Pressure 35 Bar G

For Following Set Pressure Ranges 6 Colour Coded Springs Are Available

-05 To 15 Psi = White

-15 To 35 Psi = Yellow

-35 To 75 Psi = Green

-75 To 125 Psi = Blue

-125 To 175 Psi = Red

-175 To 250 Psi = Black

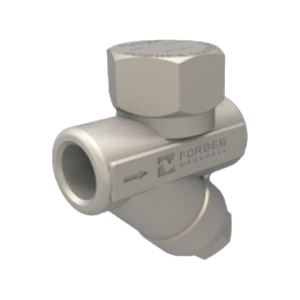

Forbes Marshall Steam Trap Fmtd64

Description

The Forbes Marshall Thermodynamic Trap Fmtd64,With Inbuilt Strainer And Full Stainless Steel Construction, Is Best Suited For Header And Mainline Drains.Also Available With Flanged Ends With Model Fmtd64fl & With Dn25 Socket Weld Ends Model Fmtd64sw25 & Is Ready To Install For Better Performance.

Sizes

Dn 15, Dn 20 And Dn25

-Screwed Bspt/Bsp/Npt & Socket Weld Ends

Notes

1. Available With Class #150 And #300 , Pn40 Flange Ends .

2. Available With Ibr Certificate

Limiting Conditions Of Fmtd64

-Body Design Conditions: Pn63

-Pma Maximum Allowable Pressure: 63 Bar G @ 100 Deg

-Tma Maximum Allowable Temperature: 4000c @ 42 Bar G

-Minimum Allowable Temperature: 0 Deg

-Pmo Maximum Operating Pressure: 42 Bar G Recommended

-Minimum Operating Temperature: 0 Deg

-Minimum Operating Differential Pressure For Satisfactory Operations: 0.25 Barg

-Designed For Maximum Cold Hydraulic Test Pressure Of: 95 Bar G

Note: For Lower Operating Temperatures Consult Forbes Marshall

-Pmob : Maximum Back Pressure Should Not Exceed 80% Of The Inlet Pressure

Under Any Conditions Of Operation Otherwise The Trap May Not Shut-Off.

Forbes Marshall Thermostatic Airvent Av53

Description

The Forbes Marshall Tracer Line Trap Fmtlt53 / Airvent Fmav53 Can Be Used For Air Venting Application From Steam Mainlines Or As A Steam Trap For Tracer Line Application For Removal Of Sub Cooled Condensate. It Comes With An Inbuild Flat Strainer Screen Having 0.8mm Diameter Perforations.

Size And End Connections

-Dn 150 And Dn 20

-Screwed Bspt/Npt, Socket Weldable Ends

Note: Available With Ibr Certificate On Request

Forbes Marshall Ci Single Orifice Ball Float Steam Trap

Description

The Forbes Marshall Single Orifice Float Trap, Soft31, Is A Cast Iron Single Orifice Float Trap Available With An Integral Automatic Air Venting Facility. It Is Available With Horizontal Or Vertical Connections With Flow Downwards. As An Alternative A Manual Needle Valve Can Be Added And Used As Steam Lock Release.

Size And Pipe Connection

Dn15, 20, 25, 40 And 50 Screwed Bspt/Npt

Note: Available With Ibr Certificate On Request

Available Types

-Soft31-T Tv With Thermostatic Air Vent (Tv)

-Soft31-S With Steam Lock Release (Slr)

-Soft31-St Combined Tv And Slr

Limiting Conditions

-Pma Maximum Allowable Pressure 13 Bar G At 220 Degree

-Tma Maximum Allowable Temperature 220 Degree At 13 Bar G

-Pmo Maximum Operating Pressure 13 Bar G

-Tmo Maximum Operating Temperature 220 Degree At 13 Bar G

-Cold Hydraulic Test Pressure: 26 Bar G

Pmx Maximum Differential Pressure

-Soft31-4.5: 4.5 Bar G

-Soft31-10: 10 Bar G

-Soft31-13: 13 Bar G

Forbes Marshall Cs Single Orifice Ball Float Steam Trap

Description

The Forbes Marshall Single Orifice Float Trap, Soft53, Is A Cast Steel Single Orifice Float Trap Available With An Integral Automatic Air Venting Facility. It Is Available With Horizontal Or Vertical Connections With Flow Downwards. As An Alternative A Manual Needle Valve Can Be Added And Used As Steam Lock Release.

Size And Pipe Connection

Dn15, 20, 25, 40 And 50 Screwed Bspt/Npt/Socket Weldable To Ansi B16.11

Flanged Ansi B 16.5 Class 150,300,600

Bs Table H,J,K,R; Din Nd 10,16,25 And 40

Note: Available With Ibr Certificate On Request

Available Types

-Soft53-T Tv With Thermostatic Air Vent (Tv)

-Soft53-S With Steam Lock Release (Slr)

Limiting Conditions

-Pma Maximum Allowable Pressure 32 Bar G At 425 Degree

-Tma Maximum Allowable Temperature 425 Degree At 13 Bar G

-Pmo Maximum Operating Pressure 32 Bar G

-Tmo Maximum Operating Temperature 300 Degree At 32 Bar G

-Cold Hydraulic Test Pressure: 26 Bar G

Pmx Maximum Differential Pressure

-Soft53-4.5: 4.5 Bar G

-Soft53-10: 10 Bar G

-Soft53-14: 14 Bar G

-Soft53-21: 21 Bar G

-Soft53-32: 32 Bar G

Forbes Marshall Compact Module Steam Trap Cmtd42

Description

The Forbes Marshall Compact Module Thermodynamic

Trap, Cmtd42m-F / Cmtd42m-S, Is A Compact Thermodynamic Trap

Module Designed With An In Built Bypass Valve, A Trap

Vent Valve And A Trap Test Valve For Steam Applications

Upto 42 Bar G. Replaceable Trap Internals And Inbuilt

Strainer Eases Inline Maintenance. The Cmtd42m-F / Cmtd42m-S

Has An Integral Upstream And Downstream Piston Valve,

Which Isolates The Upstream Piping Of The Steam Trap.

Sizes And Pipe Connections

Dn 15, 20 Socket Weldable End Connection.

(Available With # 150,300,600 Weld On Flanges On

Request)

Note: Available With Ibr Certificate On Request

Limiting Conditions

Pma Max. Allowable Pressure: 63 Bar G At 100°C

Tma Max. Allowable Temperature: 425°C At 42 Bar G

Pmo Max. Operating Pressure: 42 Bar G

Tmo Max. Operating Temperature: 425°C At 42 Bar G

Max. Operating Back Pressure: 80% Of Upstream

Pressure

Cold Hydraulic Test Pressure: 84 Bar G

Forbes Marshall Cs Prv

Description

The Forbes Marshall Pilot Operated Pressure Reducing Valves, Fmprv41 Is A Cs Iron Pilot Operated Pressure Reducing Valve Suitable For Steam Or Compressed Air.

Sizes And End Connections

-Dn 15,20,40,50 And 80

-Flanged To Bs Table J And K* Ansi 300 And 600

Din - Dn25* And 40

Note: *Dn80 Has These Flanges Only.

Available With Ibr Certificate.

Also Available For Air Applictions

Limiting Conditions

-Maximum Working Conditions 26 Bar G At 300 Deg

-Body Design Conditions 42 Bar G At 425 Deg

-Cold Hydraulic Test Pressure 52 Bar G

-Spring Range 0.2 To 24 Bar G|

Pressure Sensing Pipe

The Fmprv53 Controls The Downstream Pressure By Sensing The Downstream Pressure Through An External Sensing Pipe Taken From Downstream To The Pilot Valve Chamber (10). Fitting Of This External Pressure Sensing Pipe Is Described In The User Manual.

If The External Sensing Pipe Is Not Provided Then The Valve Controls By Internal Pressure Sensing Pipe (19). However The Capacity In This Case Will Be Reduced.

Forbes Marshall Ci Moisture Separator

Body Material:

-Cast Iron Is210 Gr Fg 260

Size:

-Dn 15 To Dn 20 Model Fmsep31

-Dn 25 To Dn 250 Model Fmsep34

Limiting Conditions:

-Table “F” Max Working Pressure 20.6 Bar G At 120 Degree With Max Working Temperature 220 Degree At 13 Bar G

-Pn10 Max Working Pressure 10 Bar G At 120 Degree With Max Working Temperature 220 Degree At 7.6 Bar G

-Pn16 Max Working Pressure 16 Bar G At 120 Degree With Max Working Temperature 220 Degree At 12.1 Bar G

-Asa 125/150 Max Working Pressure 13 Bar G At 120 Degree With Max Working Temperature 220 Degree At 10.5 Bar G

Type:

-Baffle Type

End Connection:

-Flanged Dn25, 40, 50, 65 ,80, 100, 125, 150, 200 And 250

-Available With Ibr Test Certificates, On Request.

Make:-Forbes Marshall